CNC Titanium Machining Services For Aerospace And Bicycle

- Product Item : Titaniumparts01

- Category: CNC Machining

- Type:CNC Turning and Milling

- Material: Titanium Ti 6Al-4V

- Tolerance: +/-0.05mm

- Surface Treatment:Deburring

CNC Titanium Machining Services For Aerospace And Bicycle

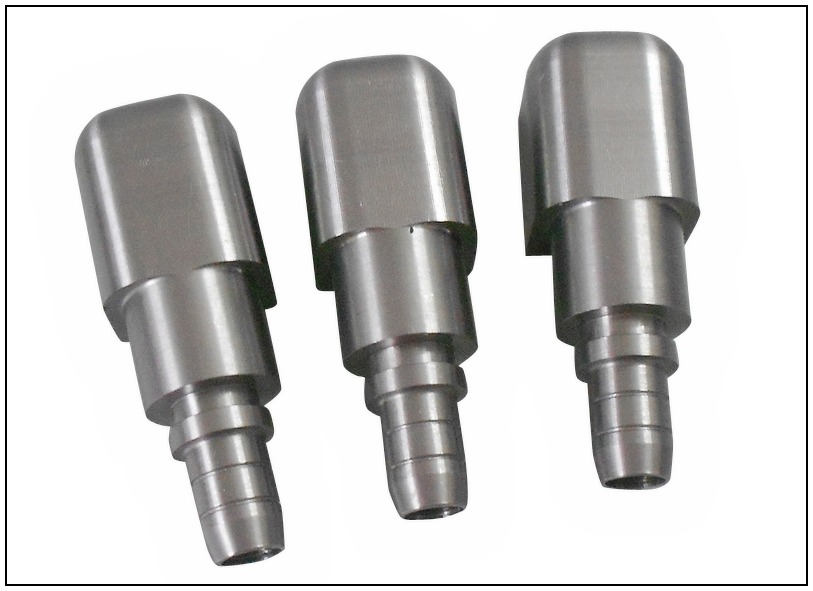

Product Name:Precision Bicycle Titanium CNC Machining Parts

Material:Titanium Ti 6Al-4V

Tolerance: +/-0.05mm

Color: Natural and customers requests.

Density:>=4.51g/cm3

Dimensions: According to customer request

MOQ: 100pcs or 300pcs

Delivery Time: 18-20 workdays after the payment.

Packing: Plastic bag + carton case, wooden case.

Why choose Xinlong?

The production difficulty and processing technology of titanium alloy CNC machining parts are very difficult.

Because of the large cutting force, high cutting temperature, small elastic modulus, uneven initial residual stress,

CNC machining deformation, difficult processing, and poor surface quality in the CNC machining of titanium alloys.

Advantages of Our Grade 5 Titanium CNC Machining Parts

– Profitable prices with ensuring high quality

– Maximum precision and production speed

– Effective solutions for different requirements

– A variety of surface finishing options for CNC titanium components

Ti 6Al-4V has a machining cost factor of 6.0 when compared to steel 12L14. It produces a fair weld and forges roughly.

Ti 6Al-4V can also be annealed, heat treated, and aged.

Titanium Grade 5, commonly referred to as Ti-6AL-4V or Ti 6-4, is a popular and versatile titanium alloy, with good

physical and mechanical properties, high strength, low modulus of elasticity, good corrosion resistance, formability,

easy to weld and be heat-treated, and light weight. It also has the capacity to join with bones and other tissue.

Based on its features,our grade 5 CNC titanium products are ideal for lots of aerospace, marine, sports equipment,

chemical processing, and medical applications.

LATEST NEWS

Contact

CONTACT USName: Linda Wang

Mobile:+86-13923762587

Tel:86-(755)-82596641

Email:linda-cnc@xl-mfg.com

Add:Liancheng Industrial Park,No.16 Shangliao Industrial Road,Shajing Baoan District,Shenzhen City,Guangdong, China